March 2023 | 2014 words | 8-minute read

One of Tata Chemicals’ many iconic advertising campaigns for Tata Salt, the category defining brand it created in 1983, equated the consumption of Tata Salt with loyalty towards the nation. The campaign, centred around ‘maine desh ka namak khaya hai’ (I have eaten the salt of the nation), not only emphasised the values of Tata Chemicals and, by extension, those of the Tata group, but also acknowledged the debt that every Indian owed the nation.

It was not an empty claim. Brand Tata Salt had arisen out of a national need to supplement the iodine-deficient diets of a large swathe of the population. The company accepted the challenge of producing and marketing iodised salt to tackle iodine deficiency disorders, rife in the country then.

The product it created went on to define the market for iodised salt in India and made a sizeable dent in the problem of iodine deficiency plaguing the nation.

"As India marches towards the landmark of becoming a $5 trillion economy, Tata Chemicals looks to participate in this journey by creating sustainable shared value for all its stakeholders with a focus on green chemistry."

—R Mukundan, Managing Director, Tata Chemicals

This is not the only instance of the company’s pioneering history. R Mukundan, Managing Director (MD), says, “From its founding, Tata Chemicals has pioneered many firsts including the indigenous manufacture of soda ash, bicarbonate, crop protection and nutrition products like iodised salt and prebiotics, and has served the nation over the years through the green revolution of the 1960s and ’70s, and the economic reforms of the ’90s, right up to the new millennium, as India emerges as a strong and self-reliant global economic power.

As India marches towards the landmark of becoming a $5 trillion economy, Tata Chemicals looks to participate in this journey by creating sustainable shared value for all its stakeholders with a focus on green chemistry.”

Serving the nation

In 2011, the company created the i-Shakti range of pulses, subsequently rebranded Tata Sampann and broadened the product portfolio to include spice powders as well. The rationale behind getting into this category was described by Mr Mukundan as, “To not only increase production of pulses in India and help bridge the existing gap between demand and supply, but also provide better quality and hygienic pulses for the Indian household.”

While Tata Salt and Tata Sampann are now a part of Tata Consumer Products following a rejig of the product portfolio, Tata Chemicals continues to prioritise the needs of the nation through its vast product line.

In fact, Tata Chemicals’ entire product line owes its existence to the goal enshrined in its vision statement, Serving Society through Science. Identifying the areas in which it could add value, the company had coined the acronym, LIFE, in 2015, to stand for Living, Industry and Farm Essentials, areas where it could harness the power of science to touch human lives.

The company set up pathbreaking innovation centres at Pune and Bengaluru to create products that intersected innovation and consumer needs. This is where the company seeks to push the frontiers of what is possible in the two verticals it operates in: Basic Chemistry and Specialty Chemistry, including Agro Sciences, Nutritional Sciences and Material Sciences.

The Nutritional Sciences division of the company, under the brand Tata NQ, launched Fossence, a prebiotic dietary fibre that improves digestive and immune health.

One of the earliest products developed by the Tata Chemicals Innovation Centre in Pune was Tata Swach, a nanotechnology enhanced water purifier developed in collaboration with the Tata Research Development and Design Centre. The product made clean drinking water available at a low cost. The Innovation Centre was driven to work towards the aim of resolving the issue of impure drinking water, an issue that is compounded by the high cost of water purifiers and the lack of awareness.

Over the years, the company established itself as the world’s third-largest producer of soda ash, also known as sodium carbonate. Soda ash is a key ingredient that has applications in several industries. It is sought by some of the world’s biggest manufacturers of soap, detergents and glass. Every fifth beverage bottle in India contains Tata Chemicals' soda ash.

Tata Chemicals is also the world’s sixth-largest producer of sodium bicarbonate. The company’s production of sodium bicarbonate is a key ingredient used by India’s biggest biscuit manufacturers.

Tata Chemicals has expanded its agri-business portfolio and grown beyond Indian shores to include Kenya and other places in its fold. What is admirable about the company's production process is that it is cognizant of its responsibility to the environment in the drought-prone areas in which it operates. Tata Chemicals draws zero freshwater for its manufacturing processes, relying entirely on the recycling and reuse of sea water. Also, since soda ash manufacturing is an energy intensive process, the company conducts frequent audits to improve the process.

In fact, the generation of fly ash, a waste product that would otherwise occupy landfills, is being converted into cement for efficient waste utilisation.

Tata Chemicals’ subsidiary Rallis also mirrors the innovation strategy of its parent company, ‘Serving Farmers through Science’. Rallis has now set itself a vision of being among the top 3 leading enterprises in specific domains within farm inputs and chemistry-led businesses by 2026. Rallis has made a name for itself as a trusted solutions provider for agri-inputs globally with an emphasis on innovation, thorough knowledge of agricultural science and a deep distribution network.

Fighting the odds

The boldness of its innovation strategy stems from the history of the company and its struggle to establish itself at a time when India was under foreign rule. By the early 1920s, the country had already begun to take meaningful steps in the iron and steel, power, textiles and other industries. The chemicals industry was the only one yet to find a foothold.

The birth of the precursor of Tata Chemicals took place on May 4, 1927, with the setting up of the Okhamandal Salt Works by Kapil Ram Vakil, one of India’s first chemical engineers. Vakil was driven not merely by thoughts of viability and profitability, but also by a vision of what India could achieve.

In 1918, Vakil joined Tata Sons as chief consulting chemist and chemical engineer and honed his expertise on the frontline of industrial chemistry. In 1923, he left the Tata group to set up a facility to manufacture soda ash. But his facility wasn’t viable and was dogged by a series of troubles. Desperate for help, he wrote to Tata Sons.

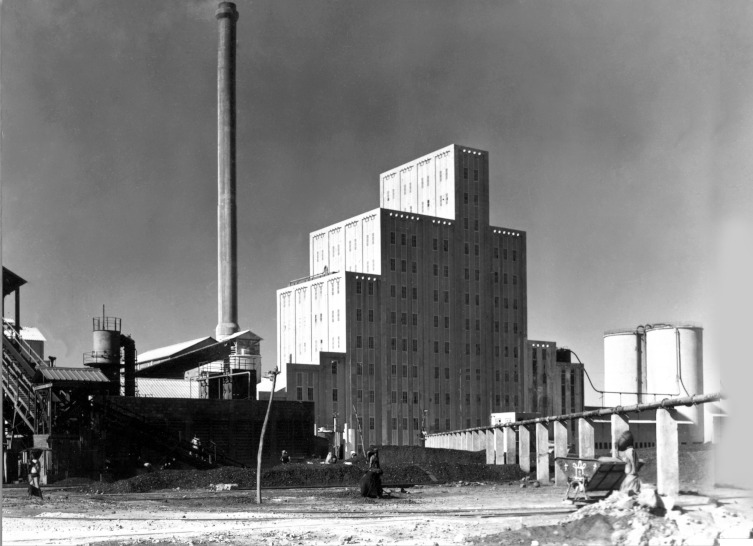

That is how Tata Chemicals became a part of the Tata group in 1939. The next few years saw the company registering steady growth. Between 1942 and 1949, the company had set up a bromine plant, the first unit in the new chemicals works; commissioned an auxiliary power plant and set up production of caustic soda, liquid chlorine, bleaching powder, hydrochloric acid and zinc chloride, as well as initiated the production of soda ash and sodium bicarbonate.

Over the next few decades, the company bided its time, building capabilities of its people and infrastructure alike and steadily growing its reputation in the market. The effort was vindicated in 1971, when the company began to sell chemicals under its own brand name. Today, Tata Chemicals is the only soda ash producing company to command a premium for its soda ash.

This has happened as a result of the company’s adoption of customer centricity as the cornerstone of its customer engagement philosophy. Customers’ unique needs are respected and adhered to, and the value created for the customer measured and communicated to them.

Beyond business

One of Tata Chemicals’ lasting legacies was its ability to look beyond business and strive for the greater good of the country. In 1974, the then MD Darbari Seth set up the Tata Energy Research Institute (subsequently renamed The Energy Research Institute) to research and develop alternative forms of energy.

In 1980, the company set up the Tata Chemicals Society for Rural Development (TCSRD), its social development arm. Over the years, TCSRD has done stellar work in uplifting the Okhamandal region, where the Tata Chemicals’ facility is located. Besides TCSRD, the company has set up other bodies such as the Okhai Centre, Uday Foundation, the Tata Chemicals Golden Jubilee Foundation, the Ncourage Social Enterprise Foundation and others, which work on social issues like clean drinking water, ensuring livelihoods and women’s empowerment.

Handmade and homegrown

In Okhamandal, a taluka in Jamnagar district and home to the company’s facility since 1939, Tata Chemicals has transformed the lives of numerous women artisans. Their handiwork, sold under the brand name Okhai now sees them firmly established as artisans and entrepreneurs.

The idea was to offer these women, living in the drought-prone area of Okhamandal, a viable source of income. Beginning in 2002, under the aegis of TCSRD, Okhai was registered as a trust in 2008, with the artisans as members.

The fledgling brand is today a collective of women artisans around the country, many of them hailing from economically and socially backward communities. The brand grew exponentially during the Covid-19 lockdowns to represent and benefit artisans in other places as well. Today, the Okhai community is 24,000 artisans strong.

It has expanded its reach to artisans in Babrala in Uttar Pradesh and Haldia in West Bengal. It is also working towards bringing the Indian Hotel Company’s weavers in Varanasi, Tata Consumer Products’ natural dye workers in Munnar, Tata Motors’ chikankari artisans in Lucknow and Tata Chemicals’ very own Masai craftswomen from Magadi in Kenya into the ambit of Okhai.

Saving the whale shark

Looking around itself, the company has been quick to adopt causes that resonate with it. The whale shark had, in recent years, been ruthlessly hunted, turning its annual visit to the waters near Porbandar on the Gujarat coast into a life-threatening proposition. The largest and gentlest of all sea creatures faced the threat of extinction.

Tata Chemicals decided to do something about it. The Save the Whale Shark campaign, a joint initiative of Tata Chemicals, the Wildlife Trust of India and the Gujarat Forest Department, is one of the most striking examples of the difference that a committed group of people can make.

The campaign saw the rescue and release of over 850 whale sharks in the waters of the Saurashtra region. Thanks to their concerted efforts, there was a decline in the cases of poaching from around 600 in 1999-2000 to zero in 2021.

Reviving the earth

TCSRD has taken upon itself the responsibility of preserving the biodiversity of the arid region of Okhamandal, to preserve the mangroves and rejuvenate the natural ecosystems.

The company’s Mithapur plant is quite close to the Gulf of Kutch Marine National Park that shelters coral reefs. Here the company runs its coral reef restoration project, mapping reef boundaries, monitoring coral growth and biodiversity and transplanting coral species into sparsely populated reef areas.

The area is also home to a biodiversity reserve plantation project, spread over 150 acres. The rampant spread of invasive weeds had pushed the native species of flora to the brink of extinction. Now the creation of this sanctuary for the native flora and fauna, particularly threatened species, has encouraged pollinators to return. The project, created over an open scrub forest ecosystem in Okhamandal, also has space for the development of microhabitats such as undulating coastal dunes and grassland patches.

TCSRD has also worked on projects around water management, rainwater harvesting, and solid waste management. Additionally, Tata Chemicals has signed up for Science Based Targets under the climate change initiative.

These are just a few instances of the company’s efforts towards the greater good. Now in its 83rd year, Tata Chemicals continues to let its actions be driven by the desire to empower the nation.

—Cynthia Rodrigues