December 2025 | 1643 words | 6-minute read

The automotive sector is facing its most disruptive decade yet. Global car makers are grappling with compressed product cycles, rising customer expectations, and a definitive shift towards electrification and software-defined vehicles (SDVs). Adding to this complexity are regulatory mandates around emissions, escalating material costs, and fierce competition from technology-first entrants.

In this scenario, artificial intelligence (AI) has emerged as the industry’s accelerant — powering everything from generative design and predictive maintenance to defect detection on the shop floor and intelligent in-vehicle systems. According to a report by Strategy& (part of PwC), implementing AI-driven transformation strategies could increase industry profit margins by 40-60%. Complementing this outlook, Precedence Research forecasts that the global market for generative AI (GenAI) in the automotive industry is expected to reach ~$3.9 bn by 2034, with a CAGR of 23.3% from 2025 to 2034.

Against this promising backdrop, Tata Technologies — riding the wave of record FY25 growth and Rs 5,168 crore in revenue, with double-digit gains in its automotive business — has positioned itself as a pivotal enabler of AI-led transformation for global OEMs and tier-1 suppliers. In September this year, it acquired Germany-based ES-Tec Group to strengthen its R&D capabilities in advanced driver assistance systems (ADAS), connected driving, and digital engineering. The Rs 776 crore deal adds 300+ skilled engineers to its talent pool and expands its footprint in Europe’s advanced automotive market.

Powering India’s EV ecosystem

As India gears up to become the world’s third-largest automotive market by 2030, Tata Technologies is embedding AI in design, manufacturing and after-sales to boost the country’s competitiveness in EVs, connected vehicles, and autonomous systems. By integrating AI into every stage of the value chain, the company is helping OEMs shorten development cycles, reduce costs, and deliver differentiated features faster. This agility is critical in a fiercely competitive, rapidly evolving global market, where AI is emerging as a decisive differentiator.

By embedding AI across the product development chain, the company is helping clients build smarter, safer, and greener vehicles. “Our vision of engineering a better world has consistently driven the adoption of emerging technologies to solve customer challenges of faster time to market by accelerating the product development timeline,” says Warren Harris, Chief Executive Officer and Managing Director, Tata Technologies. “Through this continuous innovation, coupled with deep domain expertise and global delivery capabilities, Tata Technologies has established itself as a trusted partner, helping automotive clients embrace AI-enabled engineering, transform manufacturing, and deliver smarter, cleaner, and more connected mobility solutions.”

From collaborator to change-maker

Tata Technologies’ journey in the sector has been shaped by continuous reinvention. Once primarily a body engineering partner, the company has grown into a full-vehicle engineering and AI-led transformation leader.

In 2017-18, Tata Technologies co-innovated an interactive AI and machine learning (ML) framework for one of its largest customers, empowering engineers without coding expertise to use data science in daily workflows. “This enables engineers to adopt AI tools with confidence, embed them in daily workflows and drive faster acceptance within client teams,” says Mr Harris. This early bet set the stage for its current comprehensive portfolio of 40+ AI applications, spanning design, manufacturing engineering, and after-sales.

By FY24, the company scaled beyond pilot projects to deploy advanced capabilities such as generative design, AI-driven simulation, predictive analytics, automated test generation, AI-based fault detection, real-time process optimisation, and intelligent customer engagement. These capabilities are helping its clients sharpen styling and functional layout and space utilisation studies, reduce validation cycles, optimise energy use, improve plant uptime and manage customer journeys more effectively.

AI at the core of mobility

As competition in the automotive sector intensifies with electrification, SDVs, and new entrants redefining the rules, Tata Technologies is harnessing AI to maintain its competitive edge. Its AI-enabled electrical and software systems portfolio spans the full spectrum of next-generation vehicles — e-powertrain, chassis, body, ADAS, infotainment, connectivity, and cloud solutions — accelerating innovation while ensuring safety, compliance and scalability. Capabilities include model-based development, expertise in AUTOSAR and Linux, hardware-in-the-loop testing, continuous integration and continuous delivery/continuous deployment pipelines, development, security and operations practices, and cybersecurity — all infused with AI for predictive, adaptive performance.

“By integrating AI across these offerings, we are redefining how vehicles are engineered,” says Mr Harris. “Our holistic, AI-driven approach helps OEMs deliver safer, smarter, and more connected mobility experiences — driving competitiveness in a fast-evolving global automotive landscape.”

Impact, engineered

Tata Technologies delivers solutions across predictive design, autonomous systems, real-time diagnostics, and tailored in-vehicle experiences. Its GenAI frameworks streamline code development and testing automation, helping clients cut costs, accelerate development cycles, and stay agile.

Design and virtual engineering: Generative styling, automated mid-cycle updates and AI-assisted test planning reduce repetitive work in design studios and engineering teams, while digital twins and model-based approaches compress prototype cycles in EV programmes and complex factories. Tata Technologies used these tools to achieve major efficiency gains for a client. It developed, tested and scaled a digital twin of the client’s plant to monitor operations virtually and integrated Internet of Things for predictive maintenance. This led to 30% savings in commissioning costs, reduction in on-site testing, and cut project lead time by 15%.

Manufacturing and quality: Computer vision inspection improves detection of defects and traceability, while real-time plant visibility improves equipment utilisation and throughput. Tata Technologies applied AI and ML to optimise shop floor operations for a leading global auto OEM, resulting in an 18% reduction in power consumption, 10% drop in fuel usage, and 8% decrease in chemical inputs.

Aftermarket and fleet: Tata Technologies, in collaboration with Tata Motors, has developed GenAI-powered virtual assistants that provide personalised sales guidance for dealerships. These predictive diagnostics assistants convert manuals and telemetry into real-time, actionable insights for technicians and drivers. Additionally, its Power of 8 suite — an omnichannel GenAI platform — helps OEMs improve efficiency in customer interactions by up to 95% and boosts digital lead conversions by 30%.

Hitting the mark

- AI-led optimisation cut energy consumption on the shop floor by 18% for a leading OEM, thus achieving sustainability at scale.

- It developed an AI-powered virtual sales assistant that optimised fuel usage, monitored vehicle health, and improved trip planning, leading to reduced downtime and additional revenue — Rs 1,967 crore in heavy CVs and Rs 194 crore in light and medium CVs — in a year for Tata Motors.

- The company introduced AI in the manufacturing lines of a leading US tier-1 supplier. By building predictive models, it helped minimise unplanned stoppages and reduced maintenance costs.

- In a project for a leading European luxury car maker, it introduced AI-led automation in testing and validation. This accelerated testing cycles, improved defect detection, and reduced time-to-market for next-generation vehicles.

- The company has developed WATTSync, a digital battery passport that integrates AI analytics, blockchain-secured traceability and automated compliance to enable OEMs to verify material sourcing, monitor battery performance, and track lifecycle emissions — all ahead of upcoming European Union regulations.

“These success stories reflect our belief that AI, when applied collaboratively, can reimagine processes across design, manufacturing, and customer experience, helping our partners stay ahead in the fast-evolving automotive landscape while delivering on the promise of engineering a better world,” says Mr Harris.

To strengthen its position in automotive software and deepen its engagement with global OEMs, Tata Technologies has partnered with the BMW Group to form BMW TechWorks India. Announced in October 2024, the joint venture focuses on co-developing next-generation automotive technologies. Beginning with 100 employees, the JV operates across Pune, Bengaluru, and Chennai, and is targeting a four-digit workforce by the end of 2025.

Rising to the challenge

Integrating AI into legacy automotive systems is no small feat. The industry faces a labyrinth of challenges, including fragmented and inconsistent data models and naming conventions across different systems, and disjointed information flows between mining, production, and recycling stages. Concerns around data confidentiality, intellectual property and a lack of traceability and interoperability between long-standing systems — like product lifecycle management (PLM), manufacturing execution, and enterprise resource planning (ERP) platforms — further complicate operations.

Tata Technologies’ answer to the problem is a ‘digital thread’ programme that connects PLM, application lifecycle management and ERP systems using a shared framework. This is implemented in carefully managed stages, with rigorous metrics for guidance.

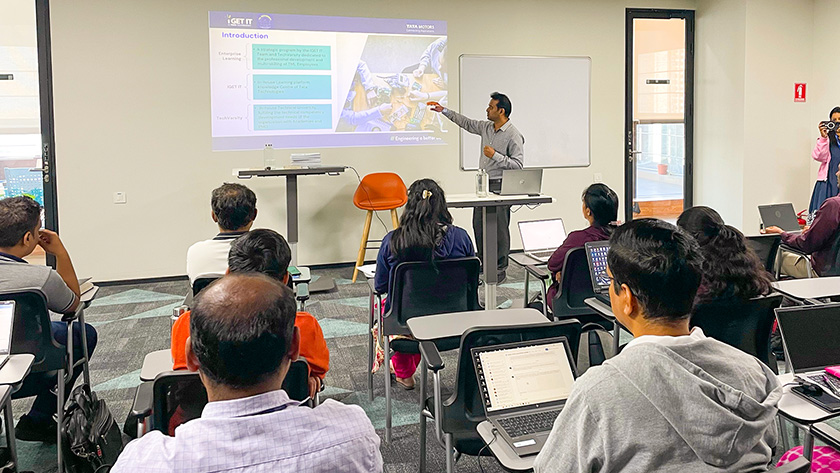

Building an AI-first culture

The company continues to expand its innovation ecosystem through partnerships with tech leaders like COVESA, AWS, Arm, Telechips, AUTOSAR and SOAFEE, as well as start-ups, innovation labs and universities. Its collaboration with IIT Hyderabad focuses on developing advanced tools to tackle challenges in building SDVs and ADAS. It also provides Tata Technologies’ engineers with upskilling opportunities in emerging technologies.

Other talent development initiatives include its TechVarsity platform, which upskilled 9,500+ of its engineers in AI/ML, data science and intelligent systems. This is complemented by its i GET IT training platform, which includes courses on AR and VR, preparing employees for AI-driven, data-centric engineering projects. Tata Technologies also encourages experimentation through its annual InnoVent Hackathon, where employees and students co-create GenAI solutions for real-world automotive challenges. Four projects from the 2024 hackathon have already been greenlit for commercialisation.

Engineering tomorrow

Tata Technologies sees the next big leap in mobility emerging from autonomous driving, vehicle-to-everything (V2X) communication, and integrated mobility platforms. With this in mind, its GenAI enterprise readiness framework is preparing OEMs to accelerate AI adoption across data, people, processes, and technology. Parallelly, the company is investing in sustainability-focused AI — from energy-efficient shop floor optimisation to digital battery passports — ensuring that future mobility is not only smarter but cleaner and in alignment with global sustainability goals.

“Together, our framework, use-case depth, and AI/ML platform create a powerful ecosystem for OEMs and suppliers to integrate AI meaningfully, driving innovation, competitiveness, and sustainable growth in a rapidly evolving global marketplace,” says Mr Harris. “This is how Tata Technologies continues engineering a better, smarter world.”

—Anuradha Anupkumar