November 2019 | 1589 words | 6-minute read

This greenfield steel plant is helping to set a new standard for the speed at which a factory can achieve full capacity from complete nascency. It also improved time-to-market by 50 percent thanks to significant investments in digital and analytics solutions, as well as capability-building to develop the digital skills of a relatively junior and inexperienced team.”

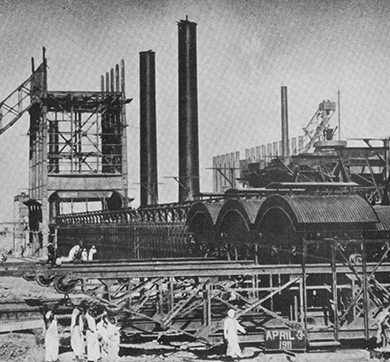

This citation refers to Tata Steel Kalinganagar (TSK) in Odisha — the first and, thus far, only Indian manufacturing plant to be recognised as a World Economic Forum (WEF) Lighthouse, a network that spotlights leaders of the Fourth Industrial Revolution (4IR). TSK was among the 10 new factories added to WEF’s Global Lighthouse Network in July 2019. They joined an existing network of 16 Lighthouses across geographies and industries, including Tata Steel’s IJmuiden plant in the Netherlands.

“These factories,” WEF said, “serve as beacons to guide others to overcome challenges in upgrading systems and applying cutting-edge technologies such as artificial intelligence (AI), big data analytics and 3D printing. They were selected based on their success in integrating these technologies to increase efficiency and drive innovation.”

The leader

Spread over 3,000 acres of land, TSK is the largest single-location greenfield steel project in India. “It has the distinction of featuring several firsts in the Indian steel industry,” says TV Narendran, chief executive officer and managing director, Tata Steel. “At Kalinganagar, we not only have state-of-the-art equipment and utilities but also drive higher productivity through automation and digital interventions. As we increase our capacity at TSK to 8 MnTPA, we will continue to implement the best technologies and innovate across the value-chain to drive operational excellence.”

The WEF recognition for TSK — like the IJmuiden plant — came in the domain of adoption of advanced analytics as a tool to create business value.

Rajiv Kumar, vice president, operations, TSK, adds, “The forethought of digital from design phase eased our entry into 4IR technologies two years ago. We set ourselves a vision to become a leader in the steel industry. We aspired for the highest performance benchmarks for the plant using digital, technology and innovation. The two-year journey across all works of life in the plant has been agile, enabling us to counter multiple challenges on the way to becoming the first and only WEF Lighthouse site in the country.”

The biggest challenges involved scaling-up of the data architecture, fast-changing operating regimes and lack of adequate data. “Fostering conviction in the power of advanced analytics to solve operational problems was a challenge that was solved through a combination of socialisation and push from plant leadership,” says Mr Kumar.

He adds, “Another major difficulty was the talent pool. With data scientists finding opportunities in major cities, hiring and retaining them remained a challenge. We aimed to upskill our own engineers to data scientists in 4IR technologies. While this has been successful to a large extent, we are still faced with the risk of attrition due to the ever-increasing demand of this skillset in the market.”

After all this, Mr Kumar and his team at TSK view the WEF recognition as an initial boost. “Most companies globally haven’t been able to sustain the momentum on digital and have failed to scale-up,” he explains. “Our aim is to make digital self-sustaining and all decision making in the plant data driven and real-time. Expansion of these to other operating aspects like inventory and spare management will be critical. We believe that in due course, the nature of any transformation will be a combination of physical and digital changes.”

To sustain this journey, TSK is now focused on modularity of data and technology architecture and creation of access to data; implementation of newer 4IR technologies like predictive solutions in equipment reliability, exploring shop-floor schedulers and robotics and automation in safety-risk areas; improving the models techniques to become self-learning models, with no need of re-training; and building an in-house world-class team of data scientists, translators and data engineers to sustain digital efforts.

Mr Kumar says, “We wish to lead the way for other Indian process plants to achieve the same feat and have organised visits for fellow Indian companies. The WEF recognition also provides us with an opportunity to learn from other recognised companies and implement newer solutions. Staying ahead of the curve is key to becoming a beacon of 4IR technologies in India.”

4IR deployments

Connected workforce: A solution developed in partnership with Tata Communications catering to all Tata Steel manufacturing and mining locations in India to track the progress of maintenance jobs in real time. This will improve the productivity of the workforce and pre-empt unsafe incidents.

Video analytics: In process video analytics is being used to identify surface defects on cold rolled products and predict ferrous content in the ore while being transported via conveyors. It is also being deployed to improve security of employees and assets across manufacturing facilities. A facial recognition and automatic number plate recognition solution is being deployed in Jamshedpur to validate identities in real time.

Maintenance technology roadmap: Developed to implement predictive maintenance, using AI, for ~20 percent of the equipment contributing to 80 percent of the unplanned delays is underway in Jamshedpur and Kalinganagar as well as the mines. This will improve the overall equipment effectiveness.

Advanced analytics: Deployed in the pellet plant to reduce bottlenecks and achieve higher consistency in raw material quality to enhance its throughput, resulting in savings worth 100 crore a year. Advanced Analytics models at the newest blast furnace (BF) in Kalinganagar have helped enhance its throughput by 7-10 percent. Additionally, a Hot Metal prediction model in the BFs allows dynamic control of the fuel rate, which helps contain CO2 emissions by reducing the consumption of coal, thereby also reducing the total cost of procured coal. These BF initiatives put together resulted in ~75 crore of cost saving in a year.

Operations research based optimisation: Such solutions are helping bring down costs through better production and transportation planning. Such initiatives together resulted in cost reduction of ~40 crore.

Plant shutdown optimisation tool: Helps schedule the optimal sequence and combinations of shutdowns by grouping upstream and downstream plants or sub-processes together to avoid losses or hot metal dumping.

AI-powered chatbots: Deployed in the domains of HR and procurement to provide information and perform basic tasks.

Robotic process automation: Being deployed across support functions like finance and accounts and human resource management to bring intelligence and agility into business processes.

Digital platforms: Tata Steel has built Compass, DigECA & Aashiyana, catering to B2B, B2SMEs & B2C customer segments. They aid the customer’s decision journey and provide better visibility of products and services. Aashiyana is an e-commerce platform for home builders and has clocked over Rs. 100 crore of sales in its first year.

Next stop

Tata Steel is in the middle of a digital technology-led business transformation to drive value creation across the enterprise with the goal of becoming agile, intelligent and smart.

Jayanta Banerjee, who moved from Tata Consultancy Services in 2018 as chief information officer of Tata Steel, says, “We started off our digital transformation journey by driving advanced analytics, which is the precursor to AI adoption. The goal is to enable insights-driven decision making via a seven-layered IT and digital strategy. The foundational elements of this strategy cut across geographies and business functions. The distinction starts appearing at the level of equipment vintage and variety.”

He explains, “For instance, TSK is a brand-new plant with state-of-the-art equipment and sensorisation. Adequate focus on data capture and storage at the design phase has considerably accelerated the journey towards adoption of advanced analytics. However, Tata Steel Jamshedpur has grown from less than 1 MnTPA to 10 MnTPA at the same location over 110 years through various phases of modernisation and, hence has facilities of various vintages and process systems that are not necessarily open or accessible. Such diversity of asset type and vintage make it challenging to implement the newer technologies at scale to derive a significant ROI thereof. However, we’re confident that in the coming years a few more of our facilities will also make it to the list of WEF’s Lighthouse factories.”

Mission 2025

Tata Steel has undertaken business transformation initiatives in the domains of integrated supply chain and logistics, connected mining, smart asset maintenance, customer-facing digital platforms, smart closure of financial accounts, smart procurement and energy management to transform how some of the underlying business processes function in the steel industry. The organisation-wide programmes are being driven by cross-functional teams from various verticals and are augmented by a partner ecosystem.

“We are driven by our goals to improve our yields, energy efficiency, throughput, quality and environmental impact of our operations. A robust, multi-tiered governance process aided by the Shikhar25 methodology (in-house continuous improvement mechanism) helps drive the digital transformation across business functions,” says Mr Banerjee.

Re-skilling and up-skilling of the employee base is being done consistently to ensure a sustainable transformation. Through multiple programmes run across geographies and business functions, the company has trained ~1,000 people across profiles of business translators, program managers, data engineers, data architects and data scientists. At present 100+ analytics models are under development, with 70+ models having been deployed. In the next 12 months, Tata Steel as a company will have ~200 algorithms deployed globally.

“The intended EBIDTA impact of this is to the tune of $2 billion over three to four years,” says Mr Banerjee. “Tata Steel is aligned to the Tata group’s objectives of Connected People, Connected Assets, Connected Operations. We intend to be the leader in Digital Steel making by 2025.”

—Monali Sarkar